Tuotetun veden suolanpoisto

Tuotetusta vedestä on tullut yksi öljyn- ja kaasuntuotannon suurimmista jätevirroista. Me TETRAssa uskomme, että optimaalinen ratkaisu tuotetun veden haasteeseen on kokonaisvaltainen käsittely ja suolanpoisto.

Suosimme suolanpoistoa mekaanisen haihduttamisen sijaan, koska se vaatii vähemmän energiaa ja mahdollistaa veden hyödyllisen uudelleenkäytön monissa muissa sovelluksissa kuin öljy- ja kaasuteollisuudessa, kuten maataloudessa, pohjavesialueiden täyttämisessä, vedyntuotannossa, teollisuuden jäähdytyksessä ja muissa sovelluksissa, jolloin jätteestä tulee resurssi.

TETRA Oasis TDS

Taloudellisesti kannattava vaihtoehto suolaveden loppusijoitukselle, jossa jätteestä tehdään voimavara.

vasemmalla: kierrätetty tuotettu vesi TETRAn tuottama vesi

TETRA Oasis -kokonaissuolanpoistoratkaisu (TETRA Oasis TDS) on patenttia hakeva ja optimaalinen kokonaisvaltainen teknologia, joka vastaa tuotetun veden - öljy- ja kaasuteollisuuden suurimman jätevirran - ylitarjontaan ja tuottaa vettä hyödyllistä uudelleenkäyttöä varten monissa eri sovelluksissa. Kenttäkokeessa, joka tehtiin eräässä suuressa yhdysvaltalaisessa liuskealtaassa, TETRA Oasis TDS:llä saatiin jopa 92 prosenttia suolapitoisesta tuotetusta vedestä, jonka liuenneiden kiintoaineiden kokonaismäärä vaihteli 40 ppm:stä 200 ppm:ään. Vertailun vuoksi mainittakoon, että tyypillinen keskimääräinen kunnallinen vesijohtovesi sisältää 300-400 ppm.[1]

Suolanpoiston lisäksi voimme uuttaa mineraaleja väkevöidystä tuotetusta vedestä (resurssista), mikä voi alentaa käyttökustannuksia ja parantaa entisestään hankkeen kokonaistaloudellisuutta.

TETRA Oasis TDS on avaimet käteen -periaatteella toimiva kokonaisratkaisu, joka on helppo mukauttaa tuotetun veden käsittelyyn, jonka syöttö-, tilavuus- ja loppukäyttömäärittelyt vaihtelevat suuresti, ja joka vastaa esi- ja jälkikäsittelyn, suolanpoiston ja mineraalien talteenoton haasteisiin ja tuottaa näin poikkeuksellista arvoa. Ratkaisumme on myös automatisoitu BlueLinxin avulla, joka tarjoaa reaaliaikaista seurantaa ja ohjausta, jolla varmistetaan luotettava suolanpoistoveden laatu ja määrä ja optimoidaan samalla koko suolanpoistoprosessin tehokkuus.

Esikäsittely

Esikäsittely on TETRA Oasis TDS:n keskeinen vaihe, jossa tuotettu vesi ilmastoidaan, jotta suolanpoistojärjestelmän suorituskyky ja pitkäikäisyys voidaan maksimoida. Koska tuotetun veden koostumus vaihtelee altaasta ja kaivosta toiseen, esikäsittelyprosessien ja -tekniikoiden joustavuus on TETRA Oasis TDS:n kriittinen näkökohta. TETRA Oasis TDS perustuu yli 40 vuoden vesikemian asiantuntemukseemme ja johtavaan asemaan tuotetun veden käsittelyssä ja kierrätyksessä, ja se tasapainottaa CAPEX- ja OPEX-kustannukset optimaalisen ratkaisun aikaansaamiseksi.

Suolanpoisto

TETRA Oasis TDS on erikoistunut valitsemaan sopivimman suolanpoistoteknologian tai teknologiayhdistelmän, jolla saavutetaan halutut keskeiset suorituskykyindikaattorit tietyssä hankkeessa.

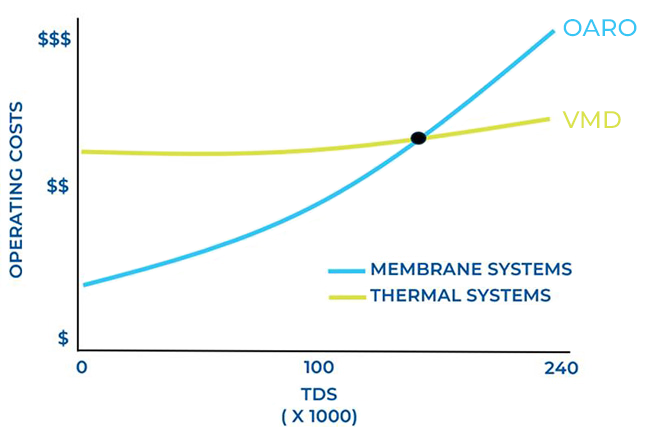

Kuten kaavio osoittaa, membraanijärjestelmien kokonaiskustannukset ovat alhaisemmat, kun liuenneen kiintoaineen kokonaismäärä on alhainen, mutta ne nousevat ylös, kun liuenneen kiintoaineen kokonaismäärä kasvaa. Sitä vastoin lämpökäsittelyjärjestelmien kokonaiskustannukset ovat tyypillisesti pienemmät suolapitoisuuden funktiona muuttuvien kokonaiskustannusten suhteen, ja ne ovat edullisia, kun liuenneen kiintoaineen kokonaismäärä on suuri. TETRA Oasis on erikoistunut tämän suhteen ymmärtämiseen ja käyttää molempia järjestelmätyyppejä tehokkuuden maksimoimiseksi koko liuenneiden kiintoaineiden kokonaispitoisuusalueella.

Voimme esimerkiksi käyttää osmoottisesti avustettua käänteisosmoosia (OARO), tyhjiökalvotislausta (VMD) tai niiden yhdistelmää optimoitujen suolanpoistoratkaisujen tarjoamiseksi.

Hoidon jälkeinen

Riippuen loppukäyttösovelluksesta, mukaan lukien pintapäästösovellukset, jotka edellyttävät onnistunutta koko jäteveden myrkyllisyystestiä, voimme käyttää erilaisia jälkikäsittelyjä suolanpoistoon tarkoitetulla vedellä jäännössaasteiden poistamiseksi.

Mineraalien louhinta

Tuotettu vesi sisältää usein arvokkaita mineraaleja. TETRA Oasis mahdollistaa näiden mineraalien talteenoton, mikä auttaa pienentämään kokonaiskustannuksia ja parantaa hankkeen kannattavuutta.

TETRA Oasis TDS:n edut:

- Optimoitu kokonaisvaltainen ratkaisu

- Vähentää hävittämismääriä maksimoimalla veden talteenoton

- Tuottaa uuden vesilähteen, jota voidaan käyttää hyödyksi myös muualla kuin öljy- ja kaasuteollisuudessa, kuten teollisuudessa ja maataloudessa.

- Integroi tehokkaasti suolanpoistotekniikat ja todistetut esi- ja jälkikäsittelyprosessit.

- Joustava pienten tai suurten tuotetun vesimäärien käsittelyyn eri syöttölaaduilla

- Automatisoitu tehokkuuden ja tuotoksen laadun maksimoimiseksi

- Mahdollistaa öljyn talteenoton ja mineraalien louhinnan toimintakustannusten korvaamiseksi.

- Vähentää kasvihuonekaasupäästöjä hyödyntämällä hukkalämpöä, kun sitä on saatavilla.

Hyödylliset uudelleenkäyttösovellukset:

|

Jätevesisuolan sovellukset:

|

Loppuviitteet

[1] https://www.epa.gov/sdwa/drinking-water-regulations-and-contaminants#Secondary

Ota yhteyttä tiimiimme

Tiimimme vastaa mielellään kysymyksiisi, antaa sinulle tarjouksen tai lisätietoja. Täytä lomake, niin otamme yhteyttä mahdollisimman pian.