Avsaltning av producerat vatten

Producerat vatten har blivit en av de största avfallsströmmarna vid olje- och gasproduktion. På TETRA anser vi att den optimala lösningen på utmaningen med producerat vatten är en heltäckande behandling och avsaltning.

Vi föredrar avsaltning framför mekanisk indunstning eftersom det kräver mindre energi och möjliggör en fördelaktig återanvändning av vattnet i olika tillämpningar utanför olje- och gasindustrin, t.ex. jordbruk, grundvattenbildning, vätgasproduktion, industriell kylning och mycket mer, vilket omvandlar avfall till en resurs.

TETRA Oasis TDS

Ett ekonomiskt hållbart alternativ till saltvattenhantering som omvandlar avfall till en resurs.

vänster: återvunnet producerat vatten av TETRA

TETRA Oasis totala avsaltningslösning (TETRA Oasis TDS) är en patentsökt och optimal end-to-end-teknik som hanterar överflödet av producerat vatten - den största avfallsströmmen inom olje- och gasindustrin - och ger vatten som kan återanvändas i en mängd olika applikationer. I ett pilottest i ett stort skifferområde i USA visade TETRA Oasis TDS upp till 92% avsaltning av salt producerat vatten med en totalhalt av upplösta fasta ämnen på mellan 40 ppm och 200 ppm. Som jämförelse kan nämnas att vanligt kommunalt kranvatten innehåller mellan 300 ppm och 400 ppm.[1]

Förutom avsaltning kan vi utvinna mineraler från det koncentrerade producerade vattnet (resursen), vilket kan sänka driftskostnaderna och ytterligare förbättra den totala projektekonomin.

TETRA Oasis TDS är en nyckelfärdig helhetslösning som enkelt kan anpassas för att hantera producerat vatten med mycket varierande specifikationer för tillförsel, volym och slutanvändning, och som tar itu med utmaningarna med för- och efterbehandling, avsaltning och mineralutvinning för att leverera ett exceptionellt värde. Vår lösning är också automatiserad med hjälp av BlueLinx som ger övervakning och kontroll i realtid för att säkerställa tillförlitlig avsaltad vattenkvalitet och kvantitet samtidigt som effektiviteten optimeras genom hela avsaltningsprocessen.

Förbehandling

Förbehandling är ett viktigt steg i TETRA Oasis TDS där det producerade vattnet konditioneras för att maximera avsaltningssystemets prestanda och livslängd nedströms. Eftersom det producerade vattnets sammansättning varierar från bassäng till bassäng och från brunn till brunn är flexibilitet i förbehandlingsprocesser och -tekniker en kritisk aspekt av TETRA Oasis TDS. TETRA Oasis TDS bygger på vår över 40 år långa expertis inom vattenkemi och vårt ledarskap inom behandling och återvinning av producerat vatten och balanserar CAPEX och OPEX för att leverera en optimerad lösning.

Avsaltning

TETRA Oasis TDS är specialiserade på att välja den lämpligaste avsaltningstekniken eller kombinationen av tekniker för att uppnå önskade nyckeltal för ett visst projekt.

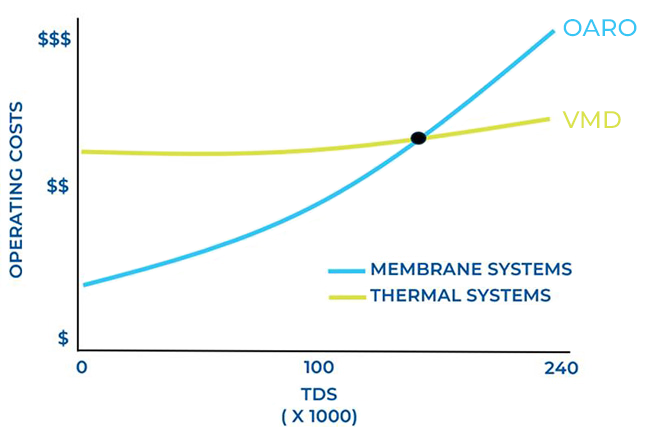

Som diagrammet här illustrerar har membransystem en lägre totalkostnad vid låga totala upplösta fasta ämnen men spikar uppåt när de totala upplösta fasta ämnena ökar. Däremot har termiska avsaltningssystem vanligtvis mindre rörliga totalkostnader som en funktion av salthalt och är fördelaktiga för behandling av höga totala upplösta fasta ämnen. TETRA Oasis är specialiserade på att förstå detta samband och använder båda systemtyperna för att maximera effektiviteten över hela intervallet för totalt upplösta fasta ämnen.

Vi kan t.ex. använda osmotiskt assisterad omvänd osmos (OARO), vakuummembrandestillation (VMD) eller en kombination för att tillhandahålla optimerade avsaltningslösningar.

Efterbehandling

Beroende på slutanvändningen, inklusive ytutsläppsapplikationer som kräver framgångsrika toxicitetstester för hela utflödet, kan vi tillämpa olika efterbehandlingar på det avsaltade vattnet för att avlägsna kvarvarande föroreningar.

Mineralutvinning

Producerat vatten innehåller ofta värdefulla mineraler. TETRA Oasis gör det möjligt att utvinna dessa mineraler, vilket minskar de totala kostnaderna och förbättrar den övergripande projektekonomin.

Fördelar med TETRA Oasis TDS:

- Optimerad end-to-end-lösning

- Minskar avfallsvolymerna genom att maximera vattenåtervinningen

- Ger en ny vattenkälla som kan återanvändas för andra ändamål än olje- och gasindustrin, t.ex. inom industrin och jordbruket

- Effektiv integrering av avsaltningsteknik med beprövade för- och efterbehandlingsprocesser

- Flexibel för behandling av låga till höga volymer producerat vatten under olika matningskvalitet

- Automatiserad för att maximera effektiviteten och kvaliteten på produktionen

- Möjliggör utvinning av skimolja och mineralutvinning för att kompensera för driftskostnader

- Minskar utsläppen av växthusgaser genom att utnyttja spillvärme när sådan finns tillgänglig

Tillämpningar för gynnsam återanvändning:

|

Tillämpningar för avfallsbrännolja:

|

Slutnoter

[1] https://www.epa.gov/sdwa/drinking-water-regulations-and-contaminants#Secondary

Kontakta vårt team

Vårt team svarar gärna på dina frågor, ger dig en offert eller ytterligare information. Fyll i formuläret så hör vi av oss till dig så snart som möjligt.