Innovative Solids-Free Fluids that Meet the Demands of Today’s Deepwater Completions

By Samy Helmy | Vice President, Fluids & Completion Services | March 25th, 2021

The selection and validation of a competent completion/packer fluid is a critical activity during the planning of deepwater, high pressure/high temperature (HP/HT) projects.

Solids-laden fluids are known to invade reservoir pore throats resulting in substantial decreases in reservoir productivity. This reservoir damage is usually very costly and in the worst cases impossible to repair. Solids within a completion fluid can also infiltrate completion equipment and tools causing malfunctions. Hence solids-free completion fluids are always recommended.

Bitter Crystals & Legacy Brines

The density of most solids-free oilfield brines can be increased above their usual supply density by simply adding more dry brine salt. However, this increase in density is always accompanied by an increase in brine crystallization temperature. Crystallization of brines within a wellbore can lead to issues with well control and/or substantial operational delays. The crystallization temperature of most high-density brines (i.e., those above their eutectic density) rises with increases in wellbore pressure. Deepwater projects pose an elevated risk of crystallization problems as brine at the bottom of the riser (at the seafloor) will experience both low temperatures and high pressures. Hence, completion fluids for deepwater projects should be solids-free and exhibit a pressurized crystallization temperature below that expected within the wellbore during all anticipated operations such as blowout preventer tests.

Historically, zinc bromide and cesium formate have often been specified as completion fluids for deepwater HP/HT projects. Although these fluids have been used successfully, both fluids pose significant issues. Zinc bromide is now classified as a marine pollutant due to its toxicity to marine species, thus its use is banned or restricted in many areas. Cesium formate is considered environmentally acceptable, but it is expensive, supplies are limited, and a number of major international oil companies have determined that formate brines are unsuitable for use, in some applications, as a packer fluid due to the risk of catastrophic tubing failure resulting from hydrogen-induced cracking.

Crystal Blue Persuasion

TETRA Technologies has developed a range of high-density, low-crystallization temperature completion fluids that are environmentally acceptable, cost effective, readily available and are viable alternatives to zinc-bromide and cesium formate fluids. These fluids are marketed under the name TETRA CS Neptune® and are ideally suited as completion fluids for deepwater and high pressure projects. TETRA CS Neptune fluids are available in monovalent and divalent forms up to 15.7 lb/gal and 17.5 lb/gal respectively. Each of the TETRA CS Neptune fluids exhibits neutral to slightly alkaline pH, stability at the temperatures anticipated within most of the HP/HT projects, and consist of readily available or renewable materials. No specialized rig equipment is required to mix, store, or use TETRA CS Neptune fluids.

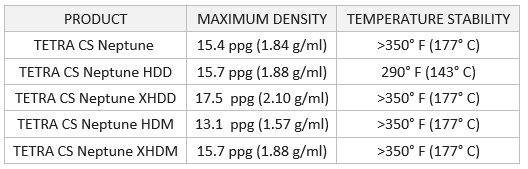

The development of our original TETRA CS Neptune fluids began in 2014 and continues today as we seek to develop additional fluids with even higher density and greater temperature stability as shown in Table 1. Our continued development of the TETRA CS Neptune family of fluids will not compromise our original goals for the environmental and operational acceptability of these fluids.

TABLE 1 – Summary of TETRA CS Neptune Divalent and Monovalent Fluids

TABLE 1 – Summary of TETRA CS Neptune Divalent and Monovalent Fluids

Success in Waves

The original TETRA CS Neptune fluid has now been successfully used in a number of ultra-deepwater wells as an alternative to cesium formate and zinc bromide brines. The first use of the fluid took place in the Gulf of Mexico in 2015. Completion and packer fluids with densities ranging from 14.4–14.9 lb/gal were required. The project’s water depth exceeded 7,000 ft, mudline temperature was 40°F, and the bottom-hole temperature was 265°F. The TETRA CS Neptune fluid designed for this project was tested extensively before use to verify its stability and its compatibility with downhole equipment and the reservoir. The fluid’s performance was exemplary during the testing phase and has continued at that level in each subsequent field application.

Completion Fluid Versatility & Setting an Industry Standard

Although developed primarily as a completion/packer fluid, TETRA CS Neptune fluids can also be used as the base brine for high-density, low-solids reservoir drill-in fluids or as carrier fluids for filter-cake breakers.

Since its introduction in 2014, the range of TETRA CS Neptune fluids has delivered exceptional operational results and has established itself as the optimal completion fluid chemistry for deepwater HP/HT projects. In 2020, we were proud to be awarded Hart’s Meritorious Engineering Award for our TETRA CS Neptune fluids.